Solutions

Wolf Group is all around you in homes, offices, commercial buildings and factories. We offer construction and renovation solutions that solve the hydrothermal issues of buildings – heat loss, air-tightness, weather resistance, vapour-tightness, cold bridges and deformations – and therefore contribute to energy efficiency. In addition, the development of our products takes into account their durability over time and the contribution they make to a healthy indoor climate. Our philosophy is to keep people´s lives comfortable, safe and running smoothly.

Decoration

Finishing works are the final step in construction or renovations, in which the interior appearance is finally formed. In many cases, the overall quality of a building is judged on the execution of its finishing. Wolf Group offers a range of elastic and crack-proof products to prepare surfaces ahead of finishing work. If used together and in the correct sequence, these products will guarantee attractive, extra-smooth, long-lasting interior surfaces. Below we show you how to achieve a high-quality interior appearance.

01

Filling low-movement joints ahead of finishing work

02

Sealing and filling joints ahead of finishing work in areas where traditional acrylics may be ineffective

03

Priming of subsurfaces

04

Insulative filling

05

Installation of skirting boards and other decorative elements

Finishing works are the final step in construction or renovations, in which the interior appearance is finally formed. In many cases, the overall quality of a building is judged on the execution of its finishing. Wolf Group offers a range of elastic and crack-proof products to prepare surfaces ahead of finishing work. If used together and in the correct sequence, these products will guarantee attractive, extra-smooth, long-lasting interior surfaces. Below we show you how to achieve a high-quality interior appearance.

01

Filling joints and cracks on stucco and other rough-textured surfaces

02

Sealing joints between various surfaces and materials

Finishing works are the final step in construction or renovations, in which the interior appearance is finally formed. In many cases, the overall quality of a building is judged on the execution of its finishing. Wolf Group offers a range of elastic and crack-proof products to prepare surfaces ahead of finishing work. If used together and in the correct sequence, these products will guarantee attractive, extra-smooth, long-lasting interior surfaces. Below we show you how to achieve a high-quality interior appearance.

01

Filling plasterboard joints and cracks

02

Filling cracks and screw holes in plasterboard

03

Priming of subsurfaces

Sanitary

When building or renovating wet rooms, special hydroinsulation products should be used to avoid moisture penetrating into structures and mould forming. Hydroinsulation products are applied directly to the floor or wall (i.e. on stone, concrete, waterproof veneer or another substrate) under the finishing layer (i.e. ceramic tiles, paint or other coverings).

01

Priming and strengthening of subsurfaces

02

Moisture barrier for humid areas

03

Waterproofing wet areas before tiling

04

Reinforcing corners, junctions and cut-throughs during waterproofing

Connecting joints need to be dealt with before finishing work is undertaken. The purpose of filling these joints is not only aesthetic but also to protect the building’s structure from the negative impact of moisture and temperature changes.

01

Filling low-movement joints before finishing

There are different joints in bathrooms that need to be protected from moisture, and even water. Some of these joints may be wide or movable, or even both. The sealing of bathroom joints depends on a number of factors and it is important to consider them all.

01

Sealing joints in sanitary rooms

02

Backing of wider and movable joints

Some materials used in interior design can be expensive and delicate, and high levels of humidity must be taken into consideration in all work, even simple adhering.

01

Sealing joints in natural stone

02

Installation and sealing of mirrors

Traditional cast iron bathtubs are common in many countries. As they are convenient, keep the water warm for a long time and are sometimes difficult to replace, it is worth renovating old bathtubs. This is not overly complicated and represents an exciting DIY project.

01

Renovating the bath tube

Floors

Concrete flooring can be used either as the final flooring layer or covered with flooring material (e.g. carpet, tiles). A concrete floor with special treatment and finishing is also an option in modern home interiors. Concrete floors with shrinkage joints are commonly used for basements, garages, warehouses, patios, and utility areas. Such flooring is durable, long-lasting and easy to clean and maintain.

01

Backing the joints

02

Sealing shrinkage joints in concrete floors

03

Increasing the wear resistance

Parquet is definitely one of the most traditional floor coverings, which gives the room an additional elegance associated with real wood. Parquet is durable and can handle heavy loads and traffic. On the other hand, wood is a natural material that expands and contracts as the humidity balance and temperature of the room change. This must be taken into account when installing the parquet floor.

01

Improving the bond and wearing resistance of the floor bases

02

Adhering parquet to the floor bases

03

Backing the joint between parquet and wall

04

Filling joints between parquet and wall

Soft floor covering materials, sold in big rolls are often the best choice – natural linoleum is suitable for children and allergic people, vinyl and PVC as durable and water-resistant flooring materials are practical in kitchens and public spaces, roll-materials can be installed quite fast and easily. Here are some suitable products and tips.

01

Improving the bond and wearing resistance of the floor bases

02

Adhering covers or carpet to the floor

03

Adhering the skirting boards

Roofs & Façades

Sealing exterior wall joints of facades against the influence of weather is very important not only for esthetical reasons, but also to protect the building structure and to save energy. UV radiation, humidity, driving rain and influences of various other factors such as chemical and mechanical loads may eventually cause damage. There can be many different façade types, for example glass façade systems, precast concrete panels with various types of finishes, brickwork and stonework, metallic cladding, tiles and stone veneer panels, etc.

01

Weathersealing

02

Backing material for weathersealant

01

Weathersealing

02

Backing material for weathersealant

Windows & Doors

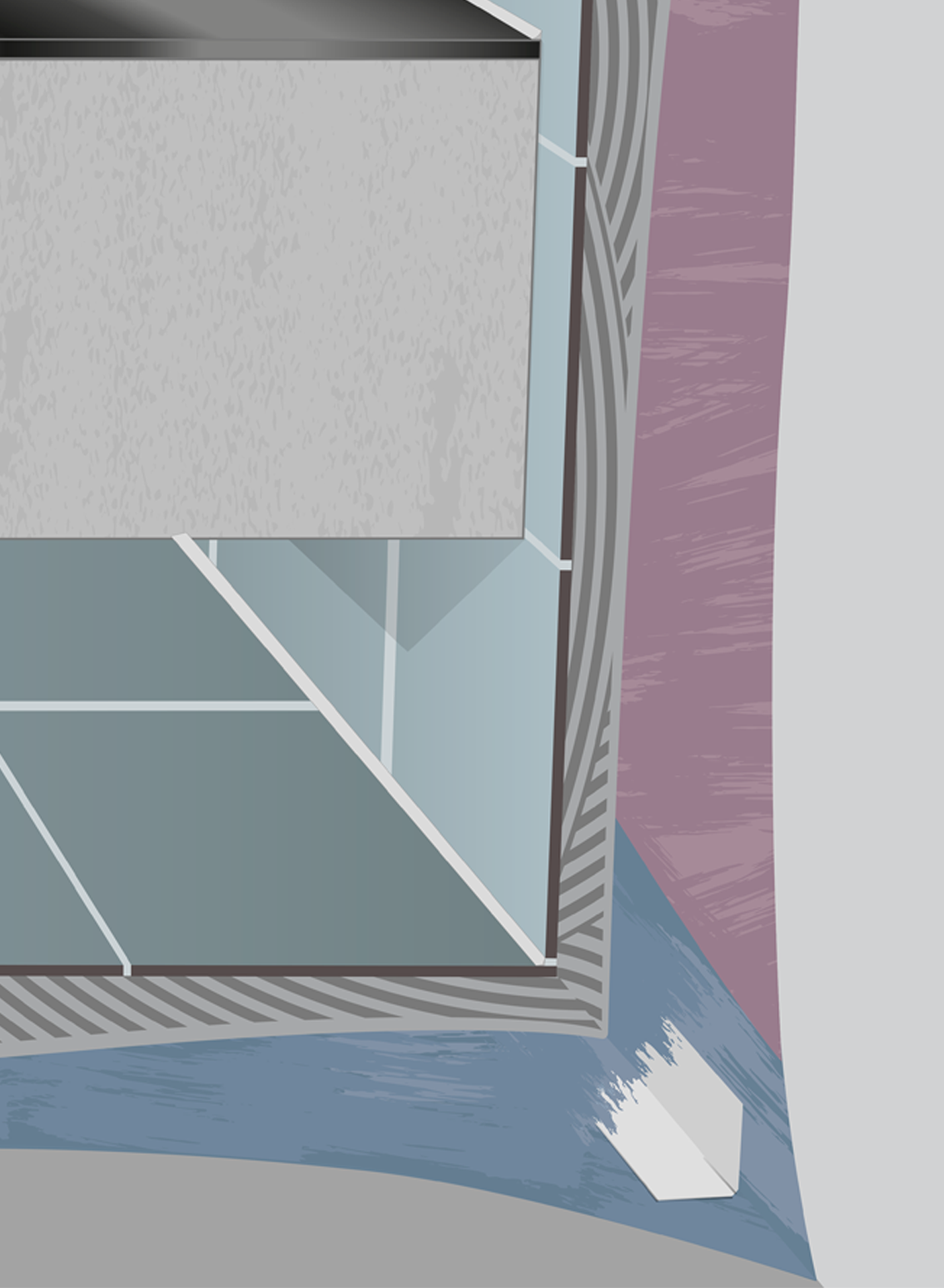

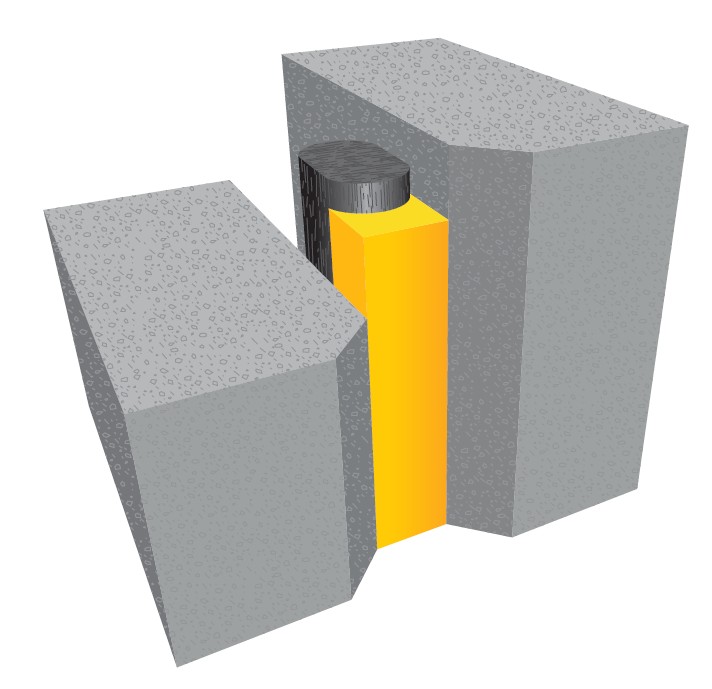

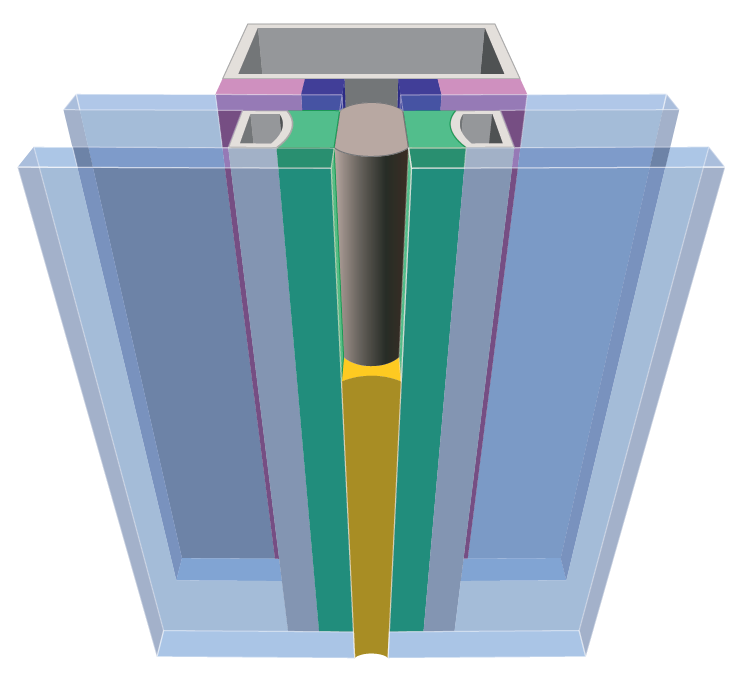

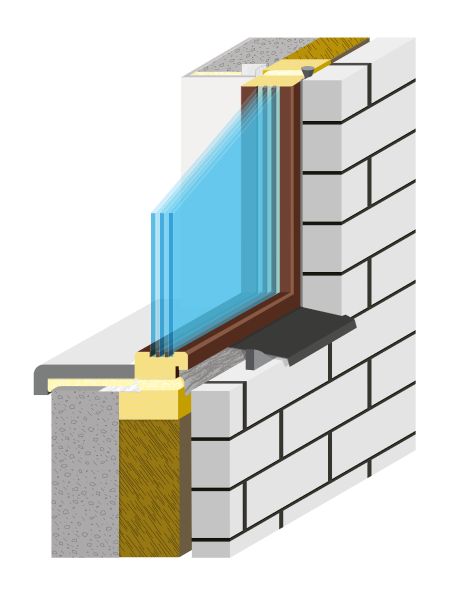

One of the most complicated and demanding joints in construction is considered to be the window installation joint. Each product performs an important and specific role to achieve the correct and energy efficient solution. Depending on the situation every product can be used individually or as a system with others, in order to obtain the greatest possible result and effect.

01

Insulating window joint

02

Ensuring air- and vapour tightness

03

Backing material for weathersealant

04

Weathersealing window perimeter

05

Glazing

06

Window tin sealing

07

Protecting from wind, rain and snow

08

Weatherproofing the joint under the window tin

09

Windowsill installation

10

Internal finishing

11

Gypsum board installation

12

Adhering vapour membrane to wall